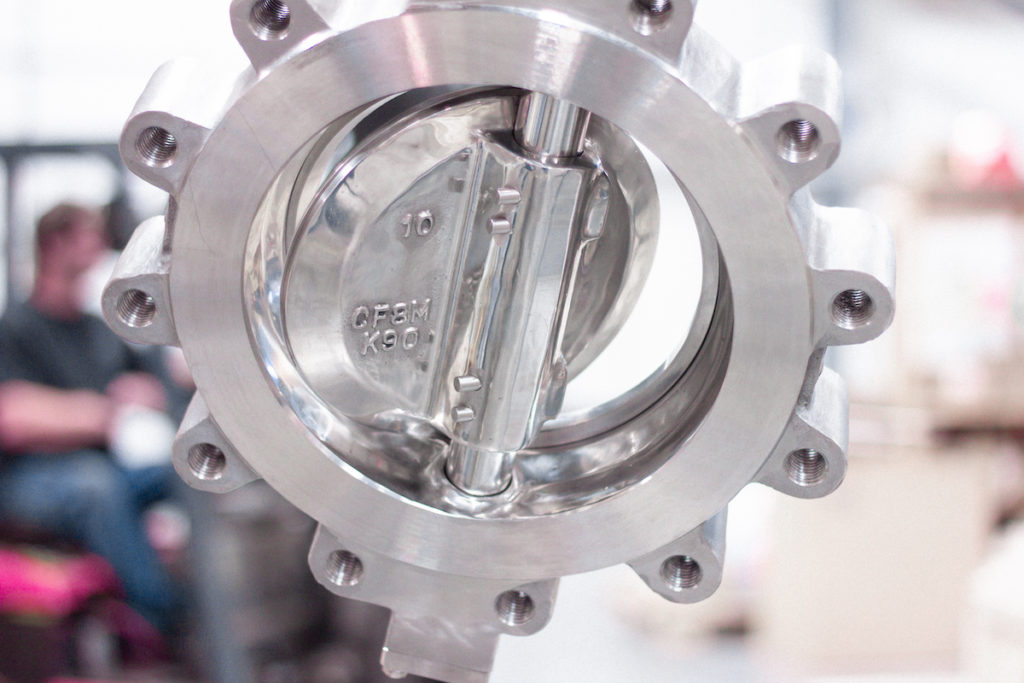

Triple offset butterfly valves are integral components in various industries, renowned for their exceptional performance in controlling fluid flow with precision and reliability. The design of these valves incorporates three offset features, which collectively enhance their efficiency and effectiveness in high-pressure and high-temperature applications. The first offset is the shaft centerline offset from the disc plane, which allows for a quarter-turn rotation of the disc. This offset results in a more efficient sealing mechanism and reduces the friction between the disc and the seat, contributing to smoother operation and longer service life. The second offset is the disc seat offset, which further enhances the sealing capability by ensuring that the disc moves away from the seat during operation, thereby minimizing wear and tear. The third offset involves the cone-shaped seat, which facilitates a tight seal when the valve is closed, reducing the risk of leakage. Manufacturers of triple offset butterfly valves employ advanced technologies and high-quality materials to ensure that their products meet stringent industry standards.

These triple offset butterfly valve manufacturers are typically constructed from robust materials such as stainless steel, carbon steel, or exotic alloys, depending on the specific requirements of the application. The use of these materials ensures that the valves can withstand harsh environments, including extreme temperatures, corrosive substances, and high pressures. The manufacturing process of triple offset butterfly valves involves precise engineering and quality control measures. The components are carefully machined to exact specifications, and the assembly process is closely monitored to ensure that the final product performs reliably. Additionally, many manufacturers conduct rigorous testing procedures, including pressure testing, seat leakage testing, and endurance testing, to verify the performance and durability of the valves. In addition to their inherent design advantages, triple offset butterfly valves offer several operational benefits. They provide excellent flow control with minimal pressure drop, making them ideal for applications where maintaining system efficiency is crucial. Their tight shut-off capability ensures that fluid leakage is minimized, which is particularly important in critical applications where leakage could lead to safety hazards or operational disruptions.

Another key advantage of triple offset butterfly valves is their versatility. They are suitable for a wide range of applications, including oil and gas, chemical processing, water treatment, and power generation. Their ability to handle various types of fluids, including corrosive and abrasive substances, makes them a preferred choice for many industries. The service provided by manufacturers of triple offset butterfly valves typically includes comprehensive support and maintenance options. This can include regular inspections, repair services, and replacement of worn components. Dombor Manufacturers often offer technical assistance to help customers select the right valve for their specific needs and provide guidance on installation and operation. In summary, triple offset butterfly valves are highly valued for their advanced design features and robust performance. Manufacturers of these valves utilize cutting-edge technologies and high-quality materials to produce reliable and durable products that meet the demands of various industries.